Our Ordering Process

Looking for custom packaging? Make it a breeze by following our four easy steps – soon you’ll be on your way to meeting all your packaging needs!

Customize your packaging

Choose from our vast selection of packaging solutions and customize it with our wide range of options to create your dream packaging.

Add to quote and submit

After customizing your packaging, simply add it to quote and submit quotation to be reviewed by one of our packaging specialists.

Consult with our expert

Get expert consultation on your quotation to to save on costs, streamline efficiency and reduce environmental impacts.

Production & shipping

Once everything is ready for production, have us manage your entire production and shipping! Just sit and wait for your order!

Manufacturing Process

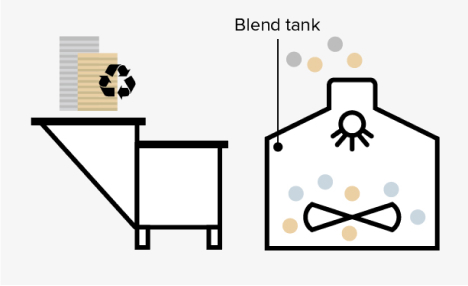

Blend

Raw material is blended and then mixed with water. Any non-fiber material is removed at this stage to create the pulp.

Mold

The machine pulls pulp onto the molds of your products. The water is then removed by applying a vacuum to set the pulp in place on the mold.

Press

The pulp is pressed and dried by two heated halves of the mold. Dry press thermoforming the product in under 10 seconds.

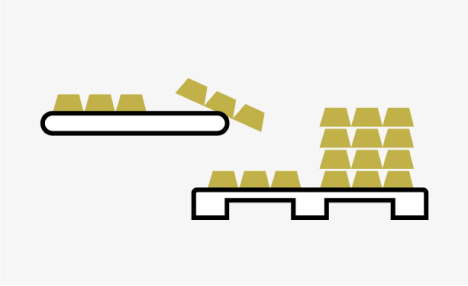

Dry

All complete dry press molded pulp inserts are inspected for quality control and then stacked on pallets ready for shipping.

Related Products

Clear Filters

Reviews

There are no reviews yet.